Innovation

BIM Modeling

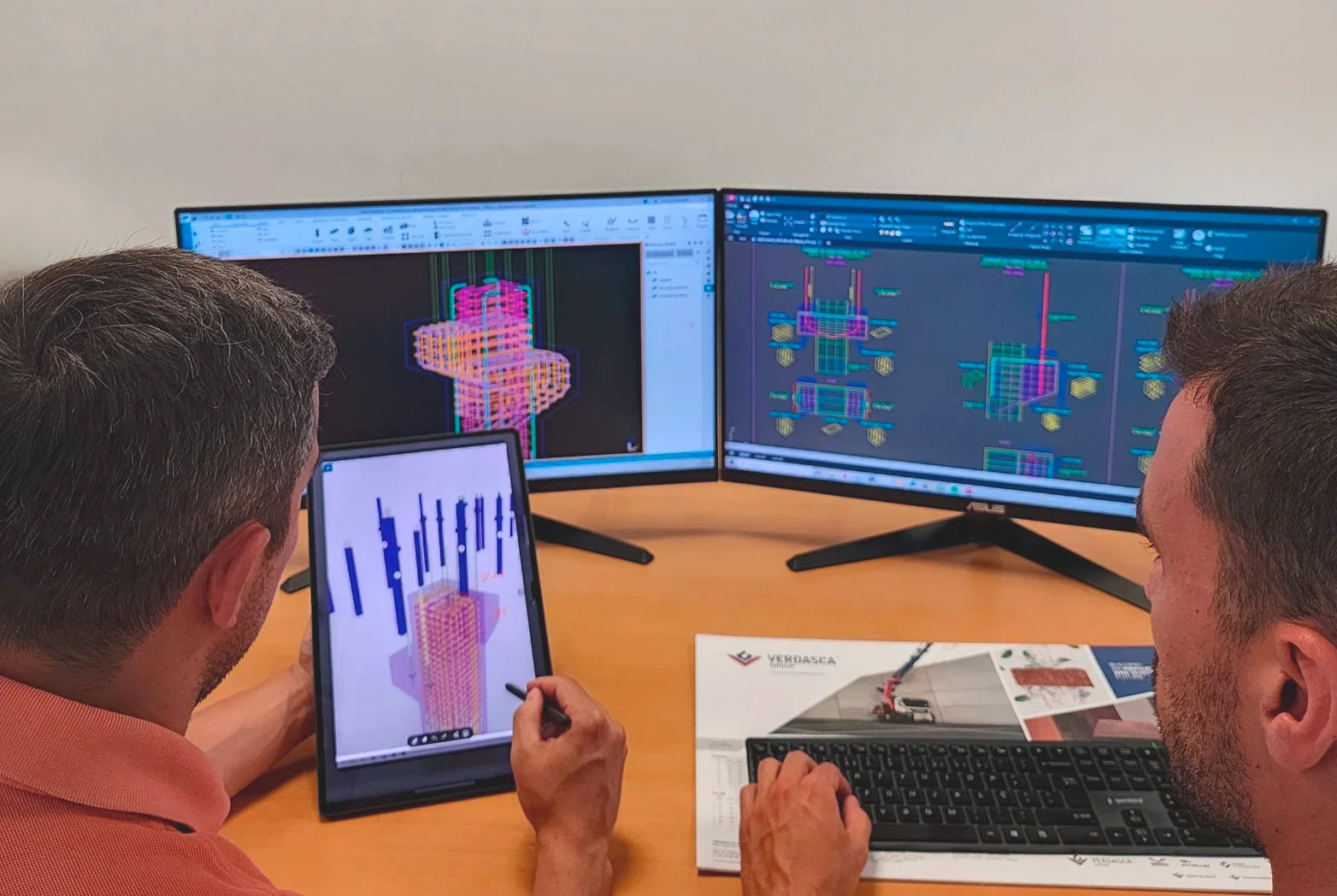

The introduction of the BIM (Building Information Modeling) methodology allows for digital and integrated management of projects, from the initial design phase to production and assembly.

This system provides greater accuracy in planning, better coordination between teams, and a reduction of errors during execution. With BIM, the production of prefabricated elements is prepared based on precise digital models, improving timelines and increasing reliability of results.

Tekla

Verdasca Group uses Tekla Structures, Trimble’s BIM software, to ensure maximum structural modeling accuracy, efficient detailing, and full integration with manufacturing workflows. This platform allows the creation of information-rich 3D models supporting the entire project lifecycle.

With integration to Trimble Connect, Tekla Model Sharing, and Reality Capture, models are shared securely and collaboratively, enabling coordination between offices and construction sites.

This technological approach allows the group to guarantee documentary rigor, agility in manufacturing preparation, and effectiveness in on-site execution, reflecting our commitment to innovation, productivity, and superior technical quality.

High-Performance Machines

Concrete panel production is carried out on high-performance robotic lines designed to ensure efficiency and quality at every stage of the process.

This line includes:

Automated carousel system for continuous element movement;

Robotic tables for product transport and positioning;

Kiln systems for controlled concrete curing;

Formwork systems allowing precision and repeatability in molding;

Automatic production line for welded wire meshes, one of the main investments in modernizing the facility;

Pile and iron cutting machines, complementing the entire manufacturing cycle with high capacity and control.

This technological setup ensures a continuous, automated production process adapted to the requirements of the most complex projects.